Been a while since I updated....early May, lockdown continues, still can’t ride, it’s very frustrating to have bikes on the drive and not ride them!!

done a few more jobs like programme the ignition advance to get a steady tick over, and importantly retard the ignition at cranking speed to give the starter motor an easier time.

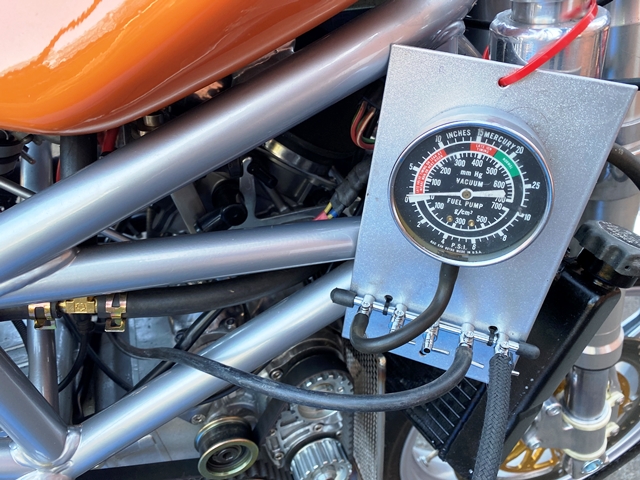

Also balanced the carbs. for years I used a mercury gauge for this but a mate borrowed them and broke it! so I bought a set of gauges, but noticed I could get it closer by ear! so I checked the gauges by connecting them to a single vacuum source and found they were all reading differently! hence the single gauge with 5 valves. the 5th valve provides damping to the gauge. I have found you can get a perfect tick over with this method.

lets hope we can ride soon!